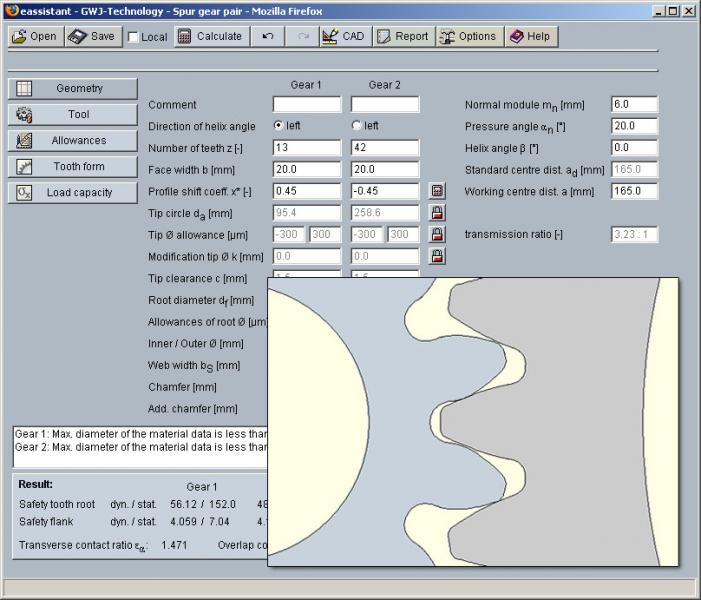

In case changes are required after the calculation and creation of the 3D model, the model can be easily updated based on the modified calculation. During generation, a tool runout can be developed. It is a quick and easy way to update 3D models during the development process. The appearance and size of that table is individually configurable. Home of Industrial Pioneers. There is no need to manually add all design table parameters to the drawing.

| Uploader: | Akiramar |

| Date Added: | 5 November 2012 |

| File Size: | 44.60 Mb |

| Operating Systems: | Windows NT/2000/XP/2003/2003/7/8/10 MacOS 10/X |

| Downloads: | 13754 |

| Price: | Free* [*Free Regsitration Required] |

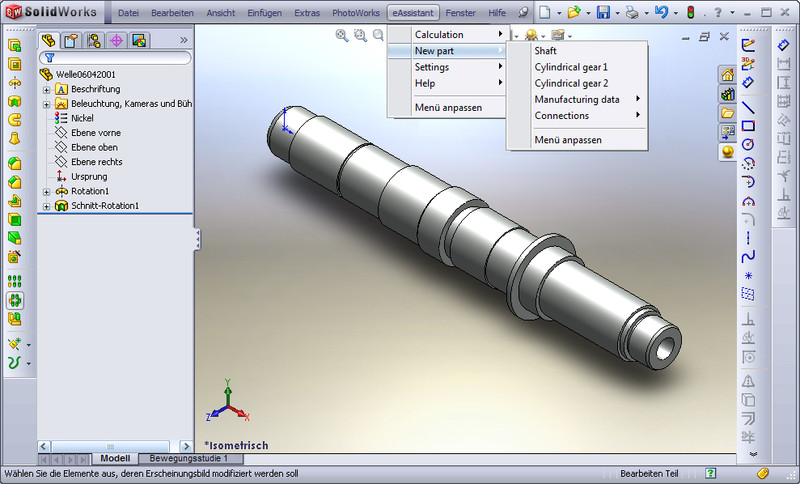

The geometry of the shaft can be defined very easily. Item could not be saved. The eAssistant allows for fast and easy calculation, design The cylindrical gears can be created as a single part or directly on an existing part. In order to give you a better service Deutsche Messe uses cookies. It is a quick and easy way to update 3D models during the development process.

GWJ eAssistant: SOLIDWORKS plugin

These products are based on our extensive and powerful technology components. Based on the calculation, the shaft and the hub profile can be created as a single part in 3D.

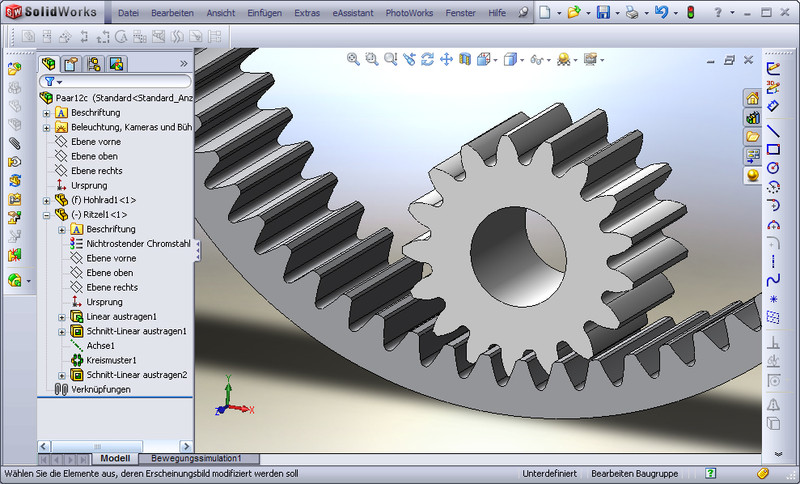

This functionality is available for external and internal spur and helical gears, involute splines as well as for hollow and solid shafts. The CAD model stores all features and dimensions as design parameters.

With just one click, the design table with all manufacturing details of cylindrical gears, bevel gears and involute splines can be placed on the manufacturing drawing. Solid and hollow shafts with an unlimited number of cylindrical and conical shaft segments can be created as a 3D part.

The plugin provides a very fast and comfortable generation of 3D shafts.

The calculation of the 3D tooth form is conducted according to a mathematical simulation of the manufacturing and rolling process. Has been already added to your Fair Planner.

More products from GWJ Technology. Home of Industrial Pioneers. The gears include the accurate tooth form. The TBK software package is a powerful and widely accepted calculation program for technical calculations for the development and design process. Share Tweet Send Share on further networks.

Based on the calculation, straight, helical and spiral bevel gears can be generated as a native 3D part in Solid Works. In addition to our own products, we create so-called OEM products by working with and for our partners.

SolidKiss_nG

The appearance and size of that table is individually configurable. There is no need to manually add all design table parameters to the drawing. Then the drawings can be delivered to the customers.

Pinion shaft with tool runout. The user gets an intelligent connection to a 3D CAD system If you continue we assume that you consent to receive cookies on all Deutsche Messe websites.

We have listed below some examples of the projects we have done in close co-operation with the partners: The eAssistant calculation including all design parameters is saved in the part and can be opened at any time throughout the entire design phase. TBK is used in Imprint Print to Top. In case changes are required after the calculation and creation of the 3D model, the model can be easily updated based on the modified calculation.

TBK The TBK software package is a powerful and widely accepted calculation program for technical calculations for the development and design process. For this purpose, the user has to specify an offset increase of the facewidth or a radius for the cutter or grinding wheel.

The bearing calculation module works completely producer-independent.

No comments:

Post a Comment